How to Choose a U-Joint

U-joints are used to connect two shafts that have a high amount of misalignment. When choosing a U-joint, consider the amount of misalignment as well as the speed (rpm) and torque the joint will need to transmit. The more the shafts are misaligned, the less speed and torque the U-joint will be able to transmit.

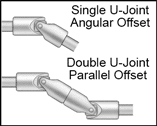

What is the difference between single and double U-joints?

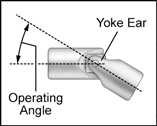

Single U-joints compensate for angular misalignment, while double U-joints (also called cardan joints) compensate for parallel misalignment. When using two single U-joints or one double U-joint, the U-joints must be installed at the same operating angle and the yoke ears must be aligned. As the operating angle increases, the working torque decreases.

Optional protective boots, also known as bellows, keep lubricant in and contaminants out.

Joint Types

- Pin-and-block U-joints work at slower speeds but transmit greater torque than needle-bearing U-joints of similar size.

- Needle-bearing U-joints operate at much higher speeds than pin-and-block and ball-and-socket U-joints.

- Ball-and-socket U-joints operate smoothly, with zero backlash (no play), so they are good for applications requiring consistent motion and precise control. They generally transmit lower torque than pin-and-block U-joints and work at slower speeds than needle-bearing U-joints.

- Geared U-joints transmit rotary motion at angles up to 136°—the widest angle of all our U-joints. They are for hand-powered, low-speed applications.

Choose from our selection of U-joints. In stock and ready to ship.